Apex

In North America, the apex of a bra will refer to the deepest part of the cup, traditionally where the nipple would rest. In the UK, the apex will refer to the highest vertical point of the cup, usually where the shoulder strap attaches.

Asymmetrical Grading

This is the grading system used on D/DD+ cup sizes where the grading increments will be applied unequally to the cup. The outer section of the cup will have larger grading increments than the inner/centre front section of the cups in order to keep the point of bust balanced. Apply a balance of of 1/3 of the measurements to the centre front and 2/3 to the outer.

Bagging / Bagged Out

A construction method where the seam allowances will be enclosed inside of the garment so that the edge does not require any further finishing. Swimsuit linings and gussets are often bagged out.

Balance Point

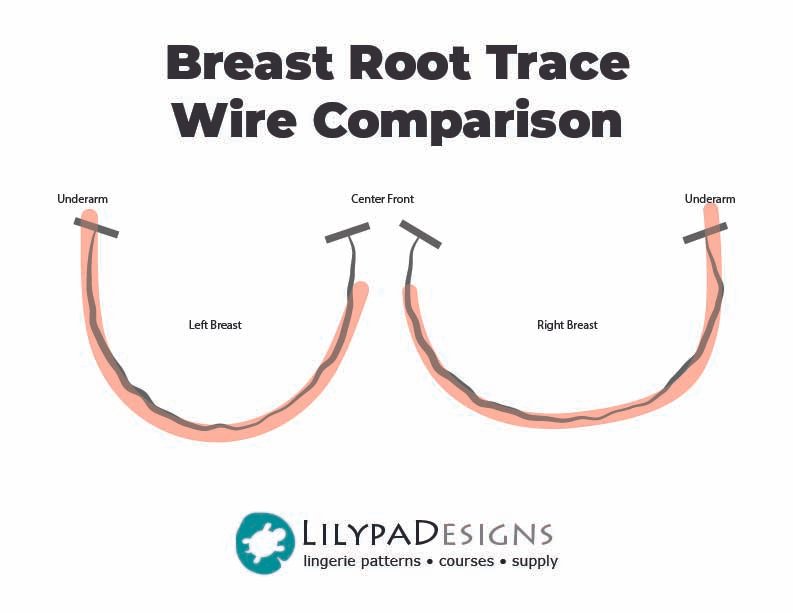

The deepest point of your underwire when resting on an X-Y axis. This point will align with the deepest part of your cup when sewn into the cradle/frame.

Band / Underband / Wing

The back portion of the bra, usually made with a strech fabric, such as powernet. Larger cups will require a firmer fabric, or two layers of a light or medium weight stretch fabric.

Bartack

A type of reinforcing stitch of a very small and tight zig zag stitch used in lingerie to secure seams, such as at the ends of elastics, shoulder straps, but most often at the ends of the wire casing to keep wires securely in place.

Bias

Cut 45 degrees from the vertical grain in fabric. In woven fabric this gives you a little stretch and also a beautiful, soft flare when you split and spread your pattern pieces.

Block Pattern / Sloper

A block pattern is a simple pattern that you can modify and manipulate into a variety of new patterns. A block pattern does not have the seam allowances on it for easier modifications.

Bobbinette / Bobbinet / English Net / Cotton Tulle

A very special tulle fabric invented by John Heathcoate in 1806. This is a uncommon material made by very few factories in the world on 100+ year old machines. Often used in couture dressmaking, corsetry, lingerie and base cloth for fine embroidery. Traditionally made of very fine cotton, it is now available in silk, nylon and special “technical” fabrics (think fishing nets and high quality wigs).

Bonding / Fusing / Ultrasonic Welding

A sew-free process using adhesive tapes, heat or ultrasounds to bind fabrics together without thread. This produces a flat, chafe-free seam, or offer waterproofing protection to outerwear.

Boning / Rigilene

Rigid strips of plastic, metal, spirals used to support garments and contour the body.

See also Flats and Spirals.

Bone Casing / Channeling

Not to be confused with wire casing or wire channeling, bone casing is wider to accommodate wider bones in corsets, basques and bustiers. It can be purchased pre-made a a tube to insert a bone, or made with a strip of bias fabric folded to make a tube-like shape. They are sewn to the garment with two rows of parallel lockstiches.

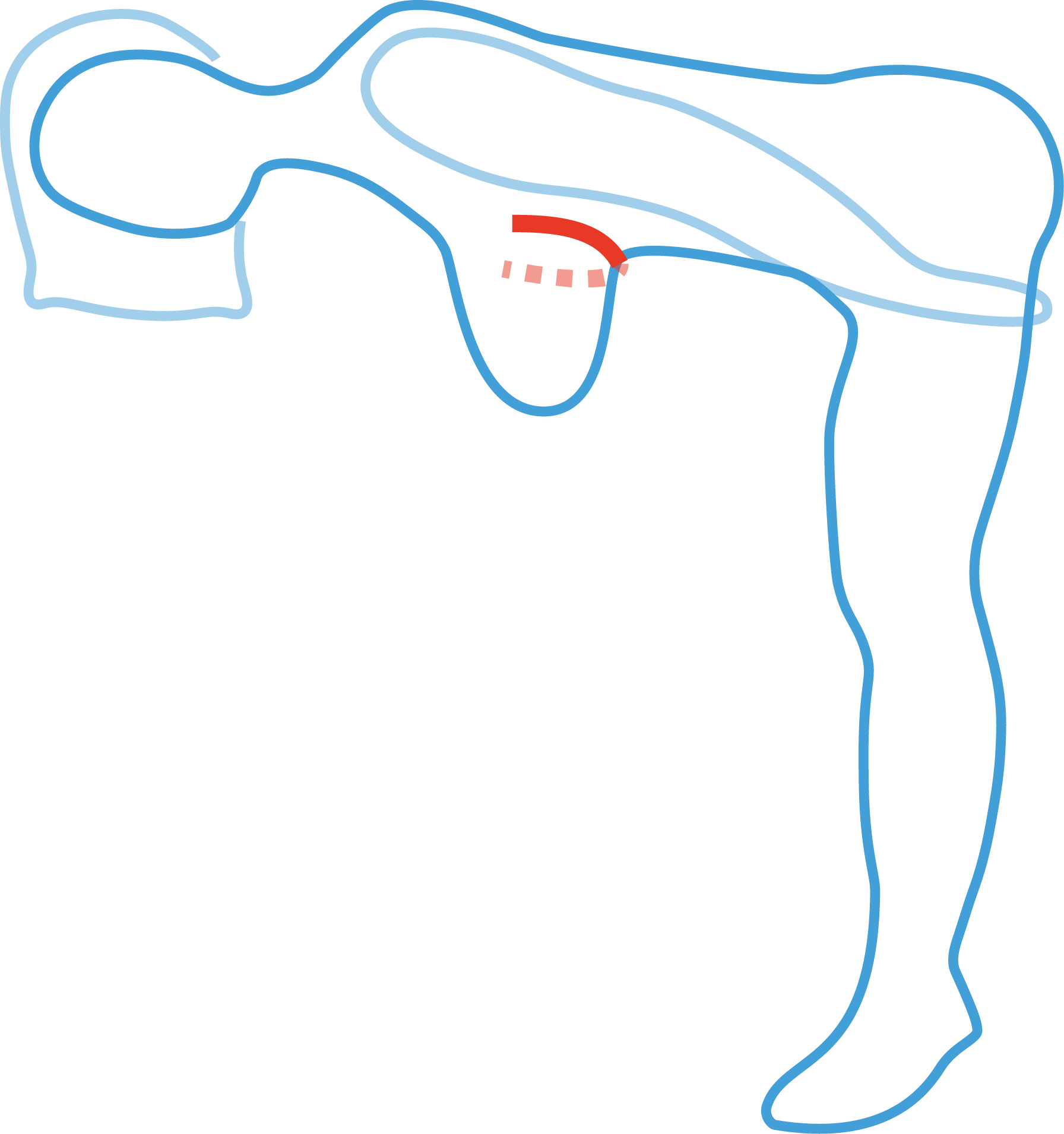

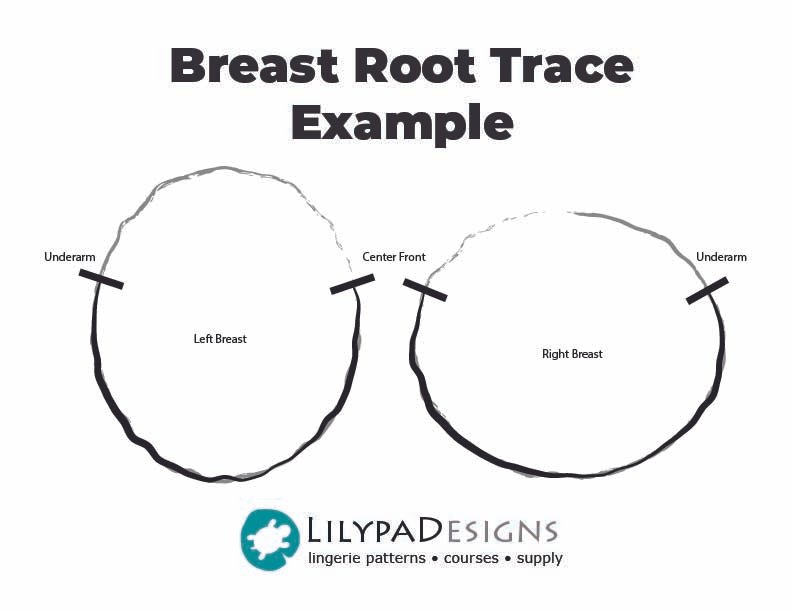

Breast Root

The breast root, or inframammary fold, is where the breast attaches to the torso. Underwires should follow the shape of the breast root for comfort. See Breast Root Trace for more details.

Busk

A rigid closure for a corset typically placed in the centre front.

Calico / Muslin / Toile

A woven, unbleached fabric that can be used for toiles and samples. It is not suitable for toiles that will end up in lightweight, woven, silk fabrics, or those with stretch. It is usually economical for sampling and is good for marking and annotating any fit or construction comments.

Centre Front / Gore / Bridge (see also Cradle/Frame)

The centre front piece of the bra, also sometimes referred to as the gore, is the fabric that connects the cups. It should be made of a non-stretch fabric for stability and support.

Chain Stitch

A chain stitch is a sewing stitch that forms a series of looped stitches with a chain like appearance. A Chain Stitch can easily be removed by pulling one thread. A Chain Stitch machine with a Nylon looper thread will sew a 'stretch' lockstitch, ideal for attaching bias bindings.

Circular Knitting Machine

A form of knitting in the round to create a seamless tube. This is how such things as socks, hoisery and seamless bodywear is created.

Compass

A drawing tool used to draw circles or arcs. This tool is particularly handy for manual pattern drafting to plot points and intersections based on measures.

Core Sizes

In lingerie, core sizes traditionally refers to cups A - D/DD and bands 32 - 38.

Coverhem / Coverstitch / Chainstitch

This machine is perfect for hemming knits as you'll get a stretchy line of stitching using 1, 2 or 3 needles and a nylon bulk looper thread. One needle will produce a chainstitch, and two or three needles will give you the hem like those on t-shirts and leggings. This machine can also be used for elasticating swimwear.

Cradle / Frame (see also Centre Front/Gore)

The cradle, or frame of your bra, is the portion of the bra to which the cups, and wires, will be attached, with the band attached to the sides. A bra with a split cradle, will have a seam underneath the breast, usually near the balance point. It is important that the centre front of a bra be made of a rigid (non-stretch) fabric.

Cross-Grading / Sister Sizing

Cup sizes are not created equal and will vary in volume depending on the band size. There will be equal or equivalent cup volumes in cross-graded sizes. Example, a 34B cup volume is equal to a 36A, 32C and 30D. Cross-grading also applies to the sizing of pre-formed cups and underwires, which is typically based on a B cup size. Therefore a '40' cup or wire, could be used to produce a bra in 40B, 38C, 36D, or 42A.

Cut & Sew Foam

A sheet of foam that can be cut and sewn together to produce a cup shape. Cups made of cut & sew foam can usually be folded inside out for packaging and transportation, or machine washed. Never fold foam, you will not have seam allowances on overbust or underarm seams.

Denier / Stabilizer / Tricot / Sheer Cup Lining / 15 denier tricot / Sheer Tricot / Marquisette

This fabric has various names and many products are incredibly similar. Be aware of fabrics that are completely rigid, and those that have a mechanical stretch. Denier is normally a strong, transparent, lightweight, synthetic, rigid fabric. It is a warp knit but it has usually be industrially finished so it has no stretch. It is used to prevent garment areas from stretching and an also be found as a tape for covering seams. Denier can be used as a backing to laminate fabrics that stretch, therefore making them rigid.

Die Cast Rings & Sliders

These components have been moulded and typically have rounded, smooth edges.

Digitizer

A digitizer will be used alongside CAD software to convert flat paper patterns into a digital pattern using a specialist board and 'mouse' or 'pen' to transfer the information electronically.

DOGS (Direction of Greatest Stretch)

This term is frequently found in home sewing bra making forums. It refers to the direction of the grain on a stable knit that has the most mechanical give.

Draping

A method to create garments by arranging fabric on the body or a dress form or stand.

Dress Form / Bust Form

A helpful tool in the sewing studio to drape fabric, model patterns on the stand, fit samples to, or display finished garments.

Ease

Allowance added into pattern pieces so the body can move.

Edgestitch / Pinstitch

To lockstitch close to a finished seam or edge.

Elastane / Spandex / Lycra

A synthetic fiber known for its incredible elasticity. Elastane and spandex are generic terms for the fiber, with Lycra being a brand name.

Embroidery

Often confused with lace, embroidery always has a base cloth of a simple net or tulle onto which the embroidery threads are stitched.

End Caps

The small steel caps will cover the sharp, cut ends of spring steel boning used for corsetry. They are available in different widths to match the widths of spiral steel. See also Spiral Steel Boning.

Flat Steels

Flat steel boning is used in corsetry, can also be referred to as Spring Steel Boning. They are made of strips of thin spring steel, with the cut ends blunted and then covered with a rust protective coating. Flat steels are available in a variety of widths, and can also be bought by the meter on a roll. See also Spiral Steel Boning.

Flexi-Curve

A flexible curve or ruler useful for drawing curved shapes, or for completing a breast root trace.

Fit Model

The person that garments are adjusted to for fit. It is important to select someone suitable to your target market, and can consistently maintain their measurements.

Fortitube

A brand of wire casing/channeling from Stretchline, known for its strength, patented as puncture resistant.

French Curve

Templates made of various curves for hand-drafting patterns.

Grading

The formulae for creating different sizes based on a single base or core size, originally invented in Germany in the early 1900s by clothing production engineers. (FAUST, M-E., and CARRIER, S. (eds.), 2014)

Grainline

On woven fabrics, the grain line is the warp thread, which is the longwise thread stretched on the loom. The 'longwise' direction of the fabric.

Greige

Fabric that has not yet been bleached or dyed is referred to as 'Greige'.

Golden Sample / Sealed Sample / White Sample

Sampling terminology will differ from company to company. Typically a golden or sealed sample will be a sample that most closely resembles the final product and may be the last sample and approved for production. A white sample may also be a final sample, only produced in an alternate colour, such as white.

High Point of Lace (HPOL) / Peak

When pattern cutting lace or embroideries with a scallop or galloon edge, it's important to plan for and mark the High Point or Peak in order to make sure that the aesthetic is as desired, and that all trims are captured within seam allowances. This is the 'highest' point in a scallop.

Hold Point

The Hold Point will be marked on a lace or embroidery pattern piece to signify an absolute for where the pattern piece must be placed on the fabric.

Hook & Eye Closure

Hooks and eyes are fairly standard in terms of design, but are available in different widths, number of columns and materials. The most commonly seen hooks and eyes have 1, 2 or 3 rows of hooks and three columns for adjustments. They do come in standard widths, 1 hook being approximately 18/19mm, 2 hooks in either 28-30mm or 38mm, and 3 hooks at 57-58mm.

Hook & Eye Tape

Also available by the meter, hook and eye tape will be required for longer closures like those on the back of basques and bustiers. They can be cut to the desired length and the edges finished with a small zig zag, like a satin stitch.

J-Hook

A specialty component for the shoulder straps of a bra. Available in both a ring and slider form, a small protruding 'J' on the back of one shoulder strap component will hook to a corresponding ring or slider on the other strap. This will result in a racerback style bra.

Knit Fabric

The fundamental unit of all knitted fabrics is the knitted loop. It is formed when a loop of continuous yarn is drawn through a previously made loop. Lingerie uses many sophisticated and technically functional knitted fabrics.

Knit / Crochet / Kohler Elastics

This type of elastic construction produced elastics with a softer stretch and modulus. They are particularly suitable for use on lightweight briefs where a more gentle finish is required. These are the ones that 'unravel' in wash & wear.

Lace

Not to be confused with embroidery, lace is woven together with a network of threads. Various widths and types of lace are available and designs can be made into stretch or rigid lace. I'm no expert on lace, so for further reading, enjoy this article.

Lamination

Bonding two or more fabrics together with a polymer film using a heated press. Delicate fabrics can be laminated to heavier, more stable linings to make them fit for purpose.

Lay Plan / Marker Making

Your lay plan will specify how the pattern pieces will be cut from the sheet of fabric to make the most out of your usage, therefore reducing waste and cost. Marker making is another name for a CAD lay plan.

Lectra Modaris

A CAD (Computer Assisted Design) program used by fashion and apparel designers. This professional software can be used to develop and grade patterns. It is highly popular for lingerie design in the industry. Competitor brands include Gerber, Assyst and Vetigraph.

Lockstitch

Industry term for 'single needle stitching'. The most common mechanical stitch.

Loop Turner

Used to make rouleau straps (see Rouleau), this long metal tool with a hook on the end can be used to turn a tube of fabric right side out. Stitch a narrow tube of fabric right sides together. Insert the tool into the tube, using the hook to latch onto the other end. Pull the fabric back through the tube in order to be right side out, using your fingers to manipulate it through.

Low Point of Lace (LPOL) / Valley

Used when pattern cutting pieces using lace or embroidery with a scalloped edge. Notations will be made on the pattern to indicate where the piece should be place. The low point, or valley, will be the lowest part of the scallop in the repeat on the finished edge.

Mechanical Stretch

Fabrics that have stretch properties but no not use elasticated yarns. The stretch is usually created in the finishing process. Some cup linings are engineered to have a mechanical stretch.

Method of Make

The step-by-step instructions on how to sew your garment.

Modulus

Describes the stretch and recovery properties of elastic materials.

MOC - Minimum Order Colour

Industry term for the minimum order of the goods per colour.

MOQ - Minimum Order Quantity

Industry term for the minimum order of the number of goods.

Modelling on the Stand

Creating ideas for garments and pattern pieces directly in 3-dimensions on a dress form or stand.

Moulded / Molded / Pre-formed Cups

Using a machine with projected barrels to mould a shape into a flat sheet of foam. A variety of shapes and sizes are available, as well as different materials. Pre-formed cups are sized like underwires, based on the B cup size.

Negative Ease

When making garments with elasticated fabrics that conform to the body, negative ease must be added for a firm fit. Therefore, the garment will be made smaller than the wearer's actual measurements.

Nylon Covered Rings & Sliders

These components have been covered with a plastic nylon coating. This coating can be dyed.

Nylon Thread / Wooly Nylon / Nylon Bulk

A 'puffy' thread used in seams with stretch. It is traditionally used as a looper thread on an overlocker/serger or coverhem machine. Some varieties can be used as a needle thread.

Overlock / Serger

A sewing machine that can use up to 5 different threads and three sewing needles. There is often a cutter to cut the raw edge of the fabric, while the stitched edge wraps around the cut edges to reduce fraying and give a clean, finished edge.

Pattern Master

A specialist ruler used for drafting patterns. Available in metric or imperial measurements, this ruler has a straight edge as well as a curved edge.

Plus Sizes

Within the lingerie industry, plus sizes typically refers to those that are D/DD+ in cup size, as well as those over a 38 inch band size.

Picot

Is a loop of thread designed for function or decoration along an edge of lace, embroidery or elastic. The loops may vary in size according to their function or aesthetic.

Plastic Rings & Slides

Plastic rings and slides are moulded from plastic. They can be produced in a rainbow of colours and some are dyeable.

Plotter Printer

A printer that will handle oversized paper available on a roll. There are various printer and corresponding paper widths available depending on your needs.

Point of Bust

The deepest and fullest point on the breast, usually the nipple. Seams on bras typically intersect with the point of bust and will be the deepest point of the cup or where multiple pattern pieces intersect. In North America, 'Apex' will refer to the deepest of the breast and bra.

Polyester Thread

A smooth and durable choice for lingerie. There are many different brands and qualities on the market. Invest in good quality thread that is smooth, free of bumps or slubs, without excess fuzz, and have a tight, smooth, consistent twist. It will keep your machine much cleaner which means fewer problems for you.

Powernet / Stretch Mesh

This knitted fabric is available in a variety of weights from extremely light and fine to ultra heavy and controlling. Powernet in various weights and modulus is commonly used in bra wings, briefs, swim, suspender belts, bustiers, basques and shapewear.

Punched / Stamped Metal Rings & Sliders

These components have been punched into their shape from a sheet of galvanized metal. They will have flat, blunt edges.

Quality Control

Throughout the production process, a number of quality control checks will be done. Fabrics will be inspected prior to making the lay plan and cutting. There may be quality control checks while machinists sew, with measurements being taken to compare to tolerances. A final quality control check will be done prior to the goods leaving the factory with a variety of points checked. Quality control checks should continue when the goods are received into inventory at their final destination.

Rings

Lingerie rings can be used to connect two pieces of fabric or elastic together for either function or decorative purposes and can come in a variety of shapes, sizes, materials and colours. Used primarily as a connector on shoulder straps to allow for the strap to freely adjust and vary strap angle. When using rings for elastics, choose a ring just slightly smaller in diameter than the width of the elastic.

Rouleau / Rouleaux / Spaghetti Strap

By cutting a very narrow strip of fabric and sewing a 'tube' you can make a small strap, loop or decorative element when turning the loop right side out. A loop turner is a handy tool for the sewing kit.

Sample Size / Base Pattern Size

This will be the size that the garments are drafted and fit to. Lingerie industry sample size is typically 34B and in the UK, bottoms a size 10 or 12.

Seam Allowances

In lingerie, seams are kept small, usually 5mm for Metric measurements, and 1/4" (approx. 6mm) for Imperial measurements.

Seamless

Seamless cups are made by using a moulded machine, like the ones used for making foam cups. Knitted garments can also be knitted in the round on a circular knitting machine. This is popular for shapewear and hoisery. Some bonded/fused/ultrasonic welded items are referred to as being seamless as they are not stitched together.

Seam Tape

Seam tape is a small strip of nylon denier that is then folded with a binder and usually stitched in place with a twin needle machine to cover the inside seam allowances on garments to add strength and comfort.

Selvage / Selvedge

Ss a self-finished edge of fabric. The selvages keep the fabric from unraveling or fraying. The selvages are a result of how the fabric is created. The selvage edge runs along the top and bottom edges of the fabric.

Slides / Sliders

Sliders are used to create adjustable straps. They can also be available, like rings, in a variety of shapes, sizes, materials and colours. Sliders with wider openings are good for very thick or textured elastics, as well as elastics that have been covered with fabrics, like on swimwear. Choose a slider that is nearest or an exact width to your elastic.

Shirring / Ruching

Gathering fabric. It can be done by using an elasticated thread as the bottom thread, wound around the bobbin.

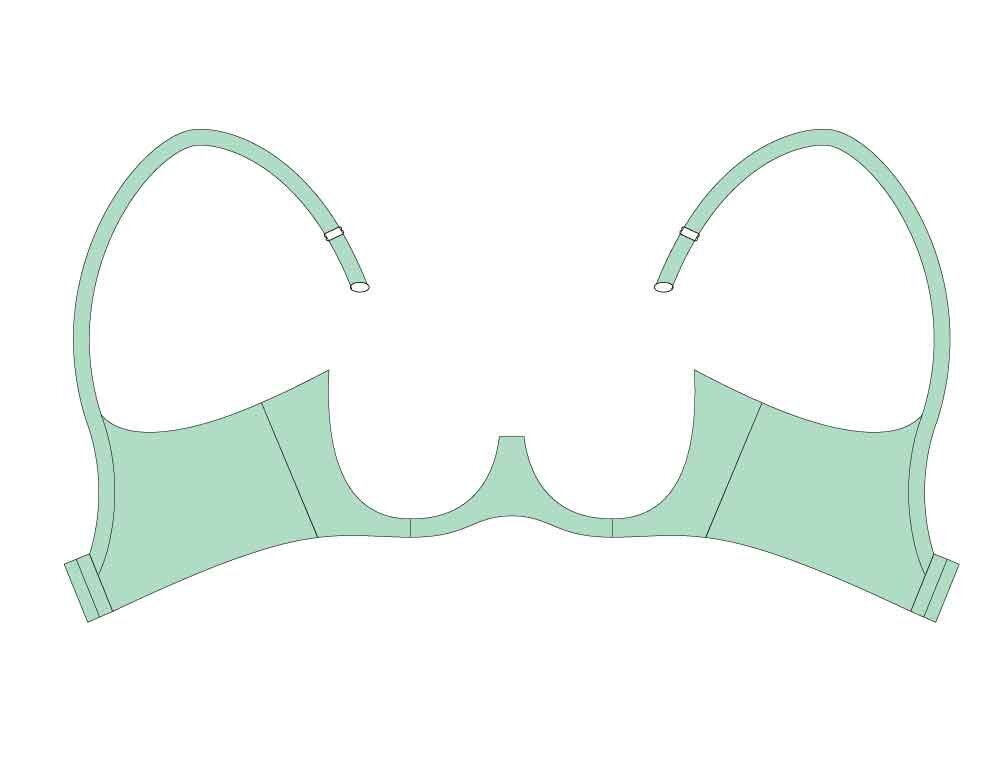

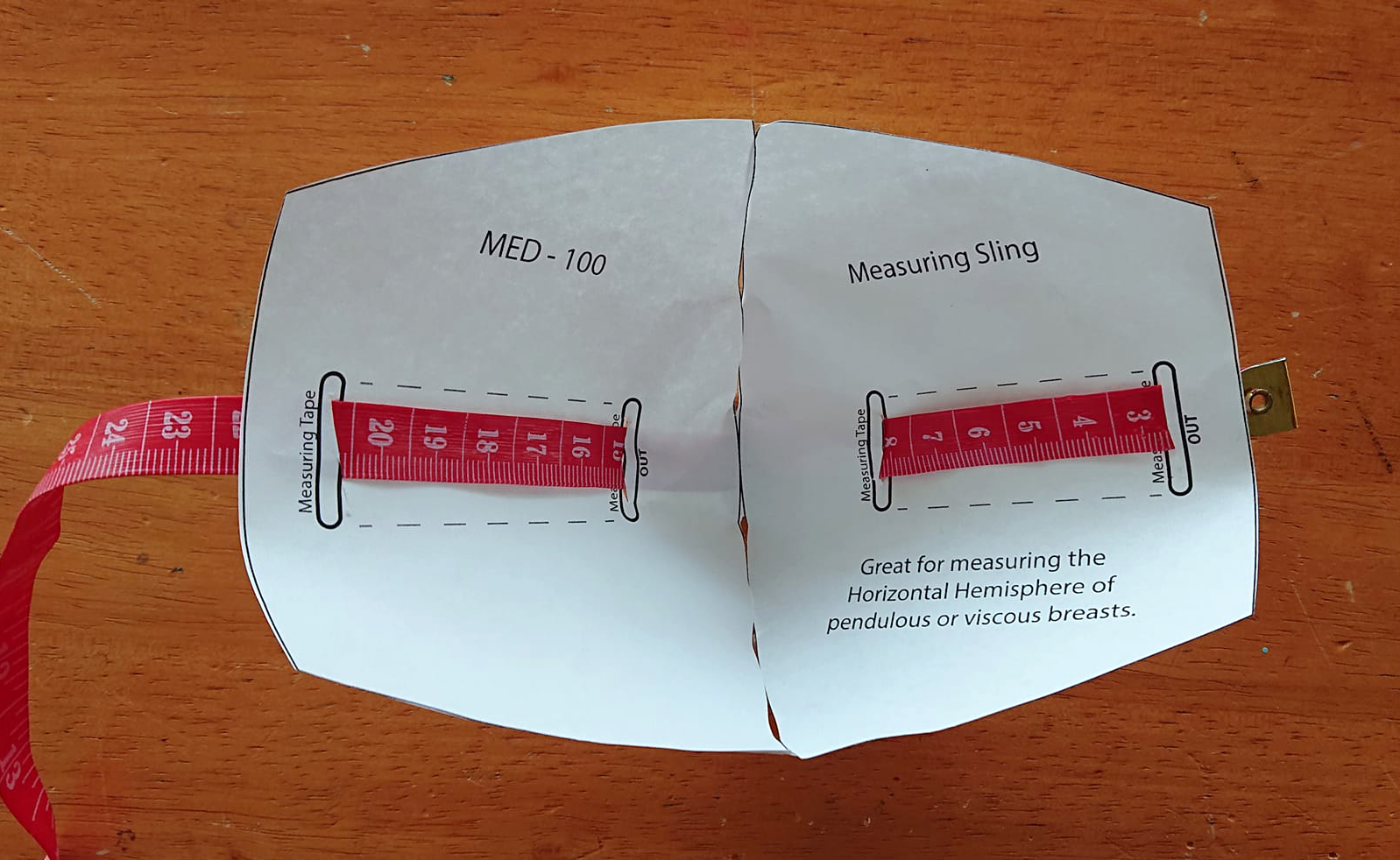

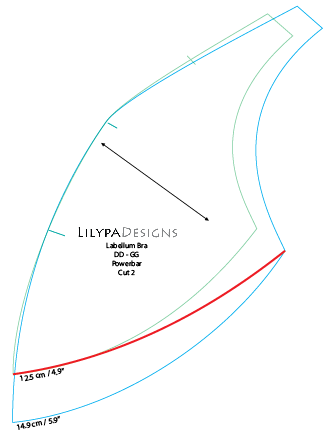

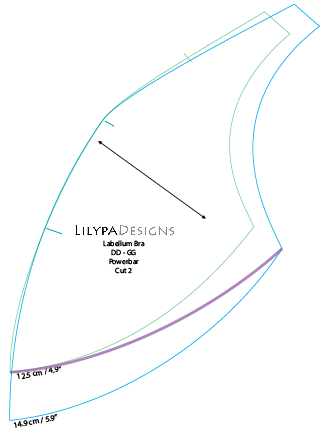

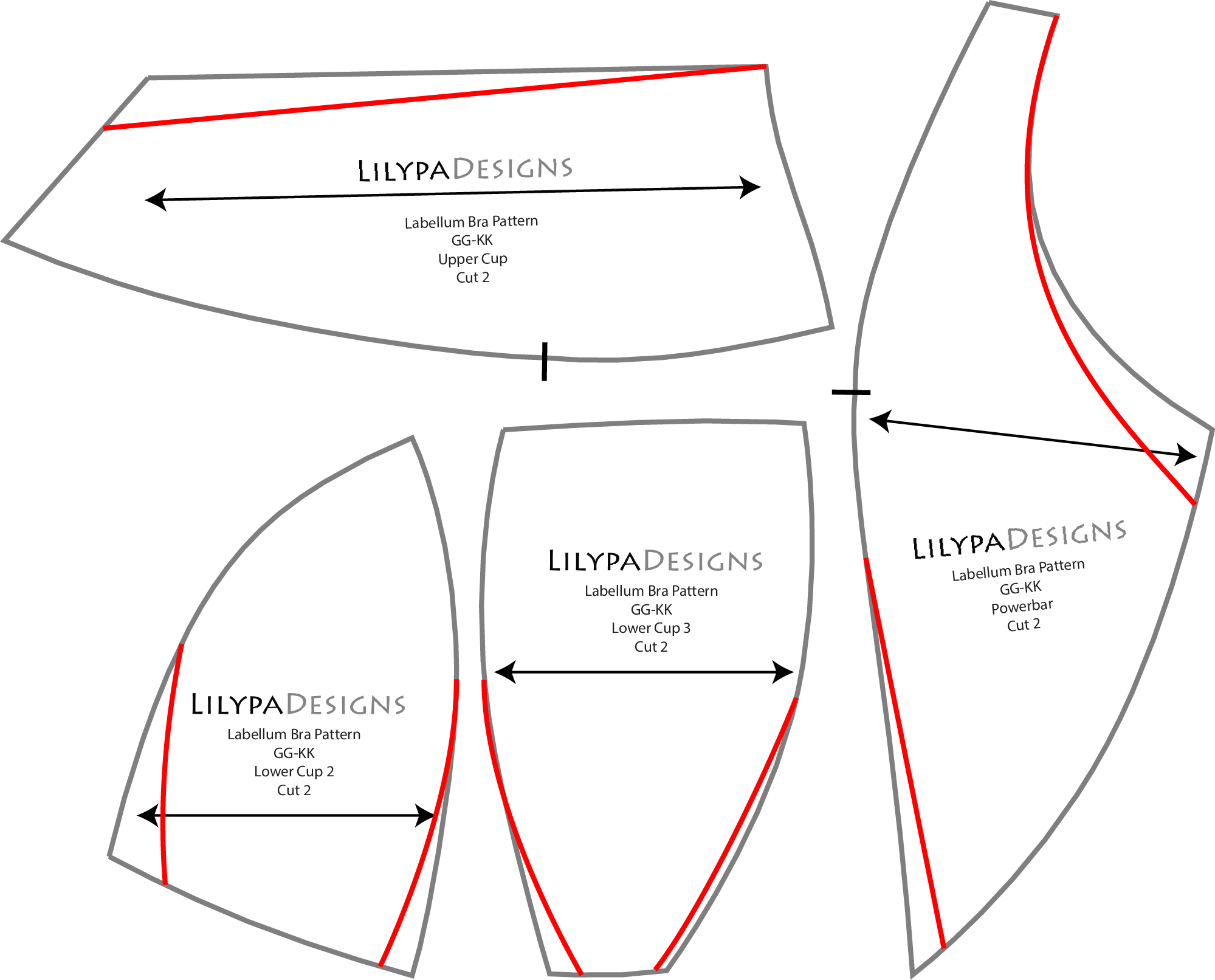

Sling / Side Sling / Side Panel / Powerbar

A cup pattern piece that runs along the underarm edge of the cup to direct the breast forward. It can be a pattern piece built into the cup, or an internal piece hidden for support, or a aesthetic element. For more information about slings enjoy this article.

Spacer Fabric

This lightweight foam can be moulded and has an inner core that is incredibly lightweight and flexible.

Spiral Steel Boning

Looks like a flattened coil, made up of a variety of small wires twisted together. It is a flexible bone used primarily in corests, basques and bustiers.

Stretch Test

A stretch test will determine the amount of stretch in your fabric or elastic and is helpful when calculating negative ease. For more information about doing a stretch test enjoy this article.

Strip-Cut Elastics

A thin film of rubber or plastic that has been strip-cut into lengths of tape. It is cheap to produce and can give a lighter or stronger finish depending on the thickness of the film. The rubber version is often used in swimwear and men's underwear. The see-through plastic (Framalon) can be used in a variety of ways, but most commonly used as a narrow colourless strip sewn to the back of a stretch lace or embroidery to give more support around a neck or leg edge.

Suspender Ends / Suspender Grips / Suspender Tabs

Traditionally a shaped clip with a rubber backer, this component will clip to the top of your stockings to hold them in place. Four is the minimum number required, one for the front and back of each leg.

Symmetrical Grading

This method of grading is most suitable for core size. Symmetrical grading will have the pattern piece grow symmetrically to the left and the right, and up and down. So, the amount of growth you add to the left, will be the same as the right, and the increment you add to the top, will also be the same as the bottom.

Technical Flats / Drawings

Technical flats are thumbnails of the garment design and typically include stitch details and back views, along with any complicated internal structures or detailing.

Technical Pack / Product Data Management (PDM)

A production technical pack can vary extensively depending on your product and the requirements of your factory. It can include such things as a method of make, usages, measurement charts and tolerances, cutting instructions, a lay plan, packaging and label requirements.

Toile

A garment sample or prototype usually made up of less expensive fabrics to test shapes, construction, fit or design details.

Tulle

A lightweight net fabric with a hexagonal structure that does not unravel. Commonly made of nylon, it is soft to the touch, strong and supportive with mechanical stretch only. Also see Bobbinette.

Tolerance

Tolerance is a plus or minus measurement used to evaluate whether the product meets a quality standard. Tolerance can be applied to pattern drafting, especially in CAD programs where seamed edges can be measured. Typically used to measure finished garments to ensure they meet specifications for quality control. For bras, tolerances are particularly small and if a garment is a few mm too big or too small, it will be noticeable in the fit.

Twin-Needle Machine

A lockstitch sewing machine with two needles and two separate bobbins to create parallel rows of stitching. This machine is used for sewing on wire casing (usually 6 or 8mm spacing between the needles) and seam cover tape (usually 6mm spacing between the needles).

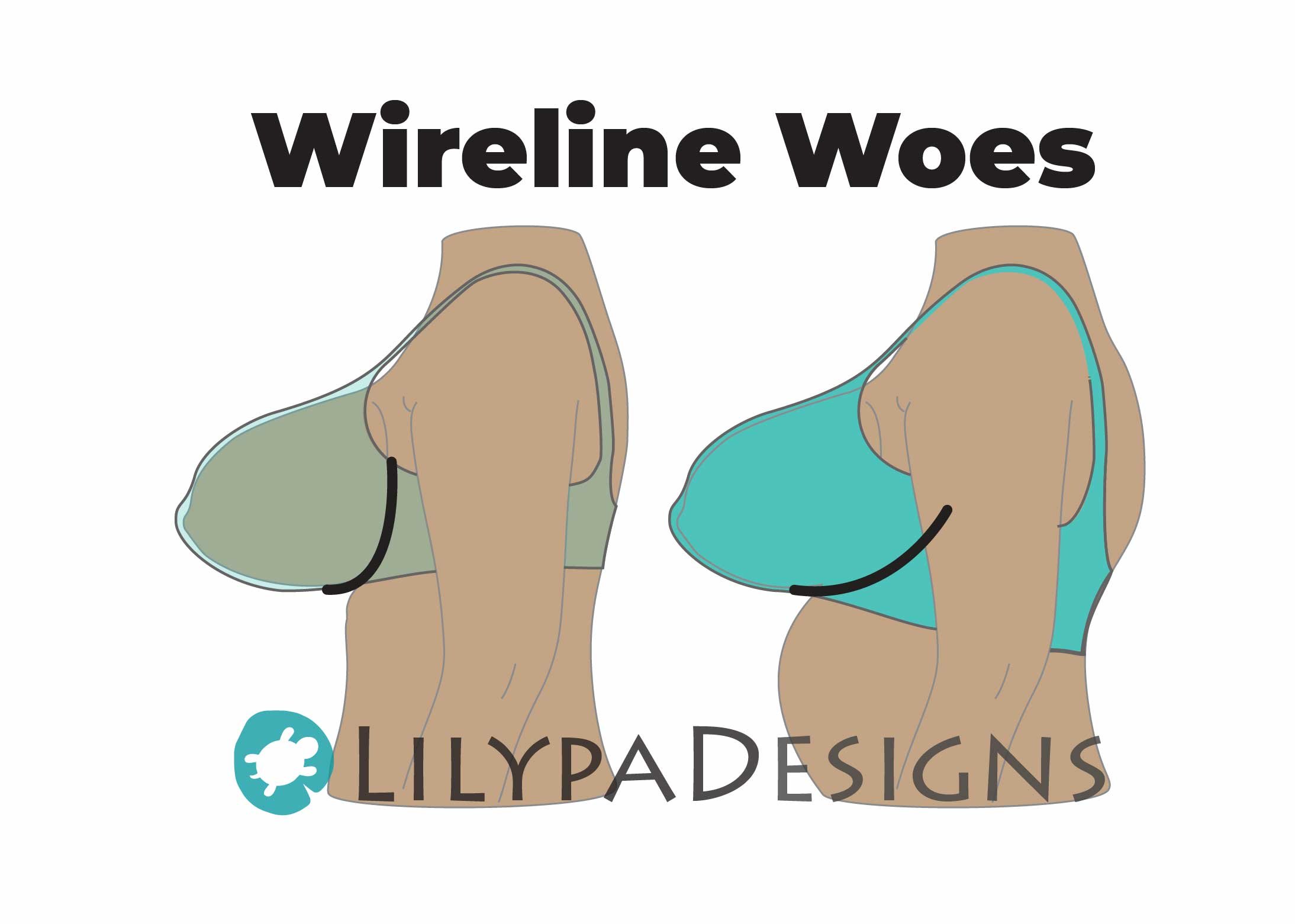

Underwire

Typically a semi-rigid wire used in bras to support the breasts. They come in a variety of shapes and sizes as well as materials, including plastic. Underwire sizing is usually based on a 'B' cup size and wires can be cross-graded to be used for all of the other required sizes.

Usage / Fabric Yield

When planning your production, you will need to calculate the usage of each fabric and trim in order to purchase and ship enough fabric for producing your goods. This will also help you determine an accurate cost price for the quantity of each material used in the product.

Useable Width

This is the width of the fabric that you can actually use for the garment. Selvages are removed and this width will be required to calculate your usage.

Warp

Warp threads run the length of your fabric.

Wastage

This will be the amount of fabric that is wasted to produce each product, as there will be a small amount of unusable fabric surrounding each pattern piece. Professional and experienced lay planners, along with specialist software can assist in plotting the best way to cut the fabric to minimize waste, which in turn reduces costs.

Weft

Weft threads run from side-to-side creating your selvages.

Wire Casing / Channelling

Wire casing is used to insert the underwire into a bra, These are tube-like fabrics that will be stitched in place with two rows of parallel lockstitches. Wire casing typically has a soft or fleecy side which is worn against the skin. There are many varieties available, and some brands include foam layers within their casing for comfort.

Wire Play

Underwires in the casing require a bit of ease for movement and flexibility. Wire play should fall between 10 and 16mm. Too much or too little wire play can result in the wire pushing through the casing, including the outer fabric of the bra.

Wire Spring / Wire Splay

When drafting a bra pattern, a wire will need to be sprung open as it would be on the body when under tension from the band. In core sizes, the wire is typically sprung under the arm upwards of 15 - 20mm. In DD+ cup sizes, the wire may be sprung both at the centre front and the underarm upwards of 5omm.

Woven Fabrics

Weaving is one of the oldest methods of producing cloth. They are formed by the interplay of warp and weft threads.

Woven Elastics

Weaving is the most flexible way to manufacture narrow elastics, carefully controlled to produce strong and stable elastics. By varying the yarns used and the structure, technical functions can be built into the product.

X-Y Axis

An X-Y axis can be used to draft and grade pattern pieces both manually and in CAD. The X-axis runs horizontally, and the Y-axis vertically.

Zamak/Zamac

This is a metal alloy made primarily of zinc, along with aluminum, magnesium and copper. This alloy composition is crucial for use in metal swimwear accessories, such as clasps, as it doesn't conduct heat as well as other metals, therefore will not get hot in the sun.

Zig Zag

A zig zag stitch is a back and forth stitch which is useful for sewing stretch fabrics. In lingerie, elastics are attached with a zig zag stitch.