Sewing Bras - Custom Drafting a Strapless Bra Part 2

A quick update on my Strapless Bra drafting adventures.

Since my last post, my fitting problems were as follows:

#6 - cups are no longer pointy but tilt downward toward the armpit despite ensuring marks on the cup lined up with the marks on the cradle. Needs to be taken in a smidge at the cross seam near center front.

#7 - bra band is ridiculously huge. It measured 30" unstretched - and that included a 12.5% negative ease for the elastic (which incidentally, I apparently pickup that percentage out of nowhere)

I had finished redrafting the bra band to better suit my tastes last round. The fit is significantly better with 2 caveats. 1) The elastic I am using is much too stretchy despite being 3/4"! It stretches 100% easily. 2) The single layer of powernet may not be enough for what I am looking for. Will entertain doubling the powernet.

#8 - tilting the cups within the frame too see if it would be enough to off set the odd angle.

The cups pointing downward (like a sad puppy) was quite vexing. After a good night's sleep, I tried on the bra again and noticed a few things I didn't previously. The bridge was too wide near the top and too narrow near the bottom. AHA! I had forgotten about the ONE alteration I always make to bra patterns as it is a necessity in order for the bridge to fit properly. Goodness I felt silly.

#9 - took in the center gore at the correct angle for my typical adjustment.

AAAAND. Still sad puppy cups. I had to step away for the rest of the day.

During my break from sewing, I got to thinking about Natasha's Underwire Theory [link

] on her blog. Specifically she talks about the importance of accounting for wire spring when drafting. While she doesn't walk you through all the steps of how to draft the bra bridge, the focus on wire spring included a different way to account for it as well as thorough explanations that I found extremely helpful. The most important lines I found was this:

"...a wire should be sprung 15mm and while this seems to be commonly repeated I have found through further education and experience that 15mm is not necessarily a rule. In many cases, it is the minimum amount of wire spring that should be added and it is possible to add up to 55mm of wire spring." - www.bramakingblog.com

compared to:

"Test the amount of splay in the wire by holding the front arm of the wire and flexing the side outward. Make a note of how much it splays. Trace the wire and then pivot the wire back the amount of the splay toward the side seam, using the bottom of the curve as a pivot point. Trace the new curve and use it for your bra draft. " - Bra-Makers Manual Vol 2.

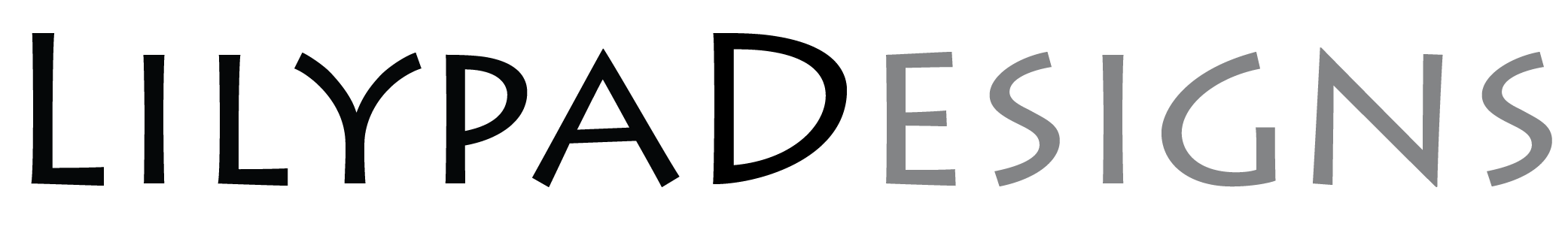

In essence, they are both stating the same thing. Bras need a little extra space in the channeling to account for the wire spring. Wire spring can differ depending on the size(length) of the wire. It would have helped my case IMMENSELY if the BMM had stated a 15 mm (smaller cups) and 55 mm (larger cups) as examples. I would have realized that my spring of 5 mm was much too small.

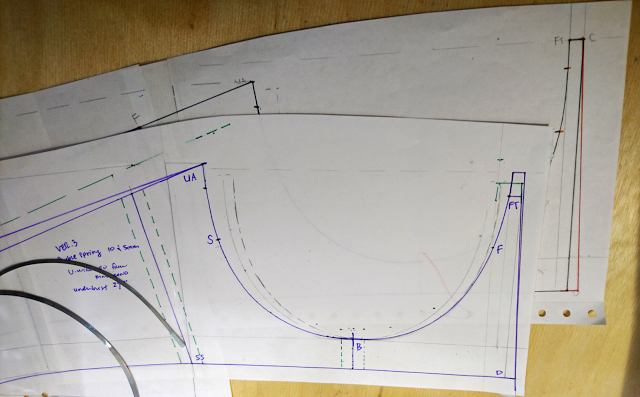

Here is the result of drafting with too small a spring vs the 15 mm.

The overall curve is flatter with the 15 mm vs the 5 mm as one would expect. However, it also LOWERS the overall height. In my case, a wire spring

(using a U-Shaped wire)

of 5 mm results in a center gore that was TALLER than the underarm - causing the droopy sad puppy eye cups!!! Hallelujah!

Green line is perpendicular to center bridge - note how one side is taller than the underarm side.

So, I think we're finally ready for some real lingerie fabrics and lace! Many thanks to Natasha and the fabulous people on the Bra Making Forum! This has definitely been my biggest bra making challenge yet!